-

사이드 라시드 아흐메드 부트샤안시 첸다 산업 오븐 (Shaanxi Chengda Industrial Furnace Co., Ltd.) 은 전기 활 오븐의 착공을 완료했으며, 노동자들은 장비를 배우고 작동하기 위해 첸다 엔지니어와 신중하게 협력했습니다.중국과 파키스탄 국민 간의 깊은 우정과 우수한 협력을 보여주는.

사이드 라시드 아흐메드 부트샤안시 첸다 산업 오븐 (Shaanxi Chengda Industrial Furnace Co., Ltd.) 은 전기 활 오븐의 착공을 완료했으며, 노동자들은 장비를 배우고 작동하기 위해 첸다 엔지니어와 신중하게 협력했습니다.중국과 파키스탄 국민 간의 깊은 우정과 우수한 협력을 보여주는. -

아부바카르1개월이 넘는 집중적인 제작과 디버깅 후,열교환연가스 퇴적실 장비 2세트가 성공적으로 운용되었습니다 ~ 프로젝트에 참여한 모든 직원이 열심히 일했습니다.~

아부바카르1개월이 넘는 집중적인 제작과 디버깅 후,열교환연가스 퇴적실 장비 2세트가 성공적으로 운용되었습니다 ~ 프로젝트에 참여한 모든 직원이 열심히 일했습니다.~ -

지완한국의 산시 첸다 산업 용기 제조 회사,노스 춘천 카운티의 귀금속 용사 오븐 장비 설치 및 신중한 제조 및 엄격한 운영, 더 많은 분야에서 상호 이익이 되는 윈-윈 협력을 달성하기 위해 미래를 기대합니다!

지완한국의 산시 첸다 산업 용기 제조 회사,노스 춘천 카운티의 귀금속 용사 오븐 장비 설치 및 신중한 제조 및 엄격한 운영, 더 많은 분야에서 상호 이익이 되는 윈-윈 협력을 달성하기 위해 미래를 기대합니다!

담당자 :

Du

전화 번호 :

13991381852

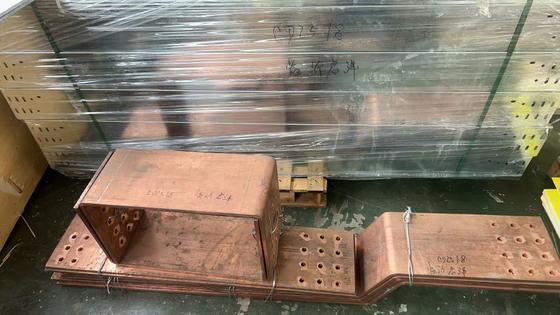

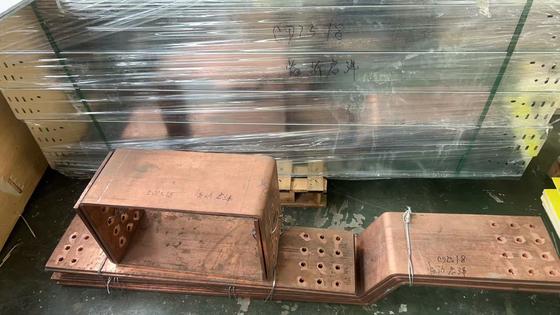

전기로 단락 네트

제품 상세 정보

| 강조하다 | 전기로 단락 네트 예비품,전기로 교체 네트,전기로 단락 네트 교체 부품 |

||

|---|---|---|---|

필요한 제품을 선택하고 게시판에서 당사와 소통 할 수 있습니다.

제품 설명